- Home

- Services

solutions for success

We pride ourselves on delivering exceptional service and expertise that drives growth and success for your business.

the features you're looking for

We take pride in offering high-quality subcontract sheet metal fabrication services, which are carried out by our experienced team of engineers. To ensure that we provide the best service possible, we employ cutting-edge technology such as:

01

2 CNC laser cutting machines from Bystronic Fiber Laser in Switzerland that are capable of cutting metal up to 30mm thick.

02

2 CNC press brakes from Hindustan Hydraulic in the Netherlands that have Delem controllers.

03

20 TIG & MIG welding machines from Migatronic in Sweden that can handle up to 500 Amps.

04

8 power pressing machine that have a maximum capacity of up to 1000 tons.

05

CNC lathes and machining centers that provide precise and accurate results.

06

In-house powder coating with 7 tank pre-treatment facilities that allow us to provide a complete and finished product.

07

CAD designing using Solidworks & AutoCAD software to ensure precise and accurate fabrication.

08

In-house spectrometer for material testing to ensure that our materials meet the required standards.

Vikas Strip Inc Services

CNC Bending

Fine blanking is a specialized type of blanking in which the blank is sheared from the sheet stock by applying 3 separate forces. As a result, high quality parts can be blanked that do not require any secondary operations. However, the additional equipment and tooling does add to the initial cost and makes fine blanking better suited to high volume production

- The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.

Vikas Strip Inc Services

SS/MS Steel Metal Fabrication

We hope to offer the best supports for the promotion of various stainless steel materials, materials processing assignment as well as import and export trading to our clients by our dry type 4 feet stainless steel sheet polishing machine, wet type 5 feet stainless steel coil polishing machine, 4 feet/800 mm automatic leveling cutting machine and other advanced processing equipment’s.

- Able to bring the ultimate performance from the advanced equipment’s.

- In order to fulfill the shortest delivery requirement for international customers.

Vikas Strip Inc Services

Coil Cut to Length

A flat sheet of material is not actually produced by a mill as a flat sheet. In reality, a flat sheet of material starts its life as part of a coil of material. A Cutting to Length Line / Steel coil auto cutting line will uncoil the material, level it, and then cut it to the required length and stack it. The end product produced by a Cutting to Length Line / Steel coil auto cutting line is a flat sheet of material cut to a very precise length tolerance.

- Fixed roll or quick-change cassette leveler with high plastification rates

- Specific stacking technology (air-floatation, vacuum or magnetic)

Vikas Strip Inc Services

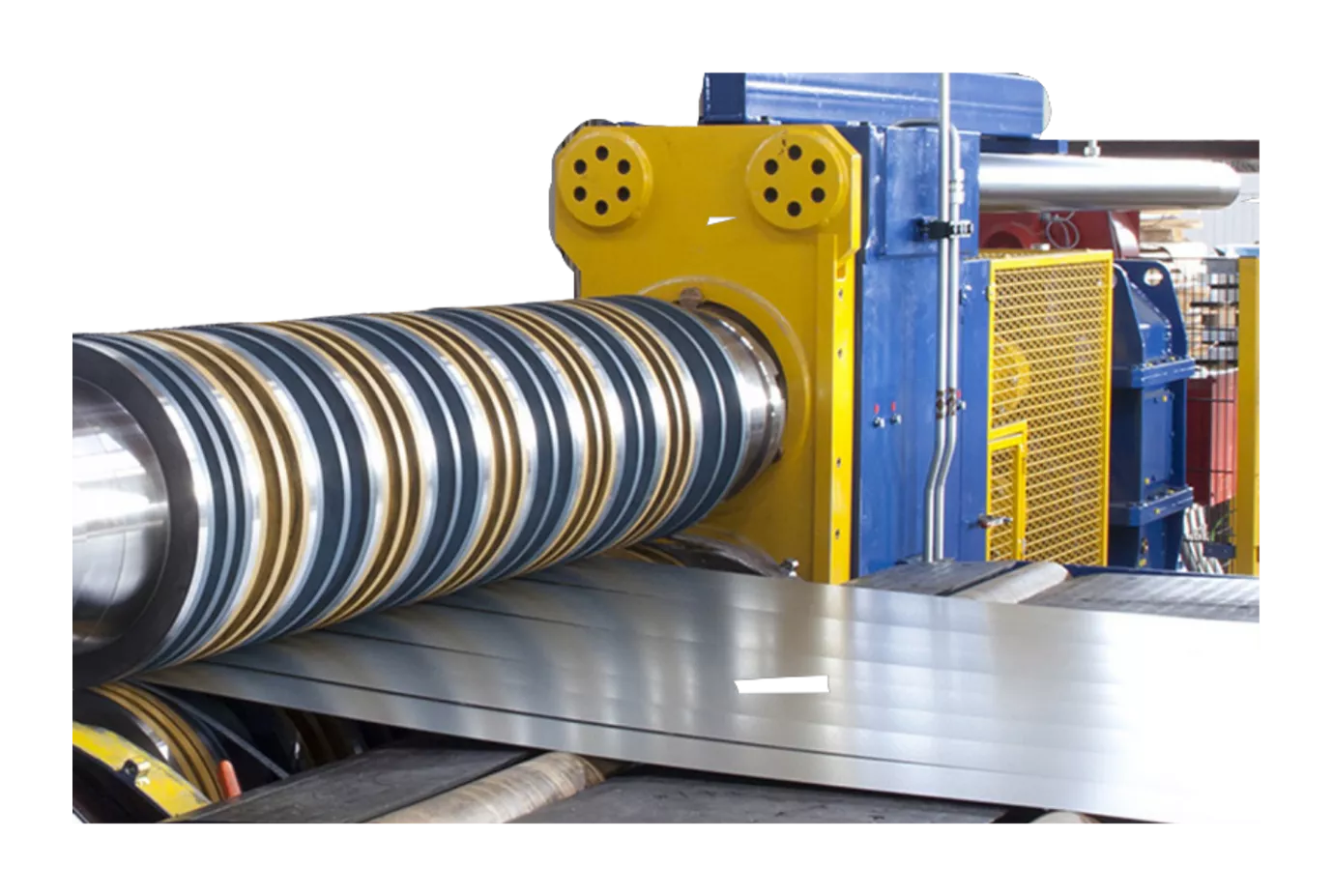

Slitting Machine

The slitting line is used for coil with different specifications, through uncoiling–slitting–recoiling to any needed width coil. Slitting line is widely applying in metal plate processing industry, like auto car, container, household application, packing, construction material, etc. Applied to process various of metal coil, such as cold rolled steel, hot rolled steel, stainless steel, galvanize steel, aluminum, silicon steel, colored steel or painted steel.

- With the reasonable layout, fully automatic, high efficiency, high productivity, high precision, high quality, steady running, easy operating.

- Imported high-performance Mitsubishi PLC control system is used to realize global control.

- The Year of Installation is 2019

Vikas Strip Inc Services

Turret Punch

A turret punch, also known as a turret press, is a metal shaping machine that utilizes punching to create various shapes. This process involves the insertion of a punch through the metal, resulting in the formation of a hole. To secure the metal, a die is often placed on the opposite side of the hole. With its versatility, the turret punch can produce holes of different diameters and efficiently create numerous holes in a metal sheet, catering to the specific requirements of your fabrication needs.

- Innovative energy renewal principle: surplus energy from the brake processes is buffered and used to accelerate the tool again.

- Suitable as an introductory punching press due to its low acquisition cost and longevity of the construction.

- Year of Installation is 2019

Vikas Strip Inc Services

Laser Cutting

Laser cutters produce metal parts from sheet material using a laser beam to vaporize sections of the workpiece. offers a cost-effective cutting solution whether you need a single part, batch of prototypes, or a production order.

- The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.

Reference Value of Bend Length by Material Thickness

Vikas Strip Inc Services

CNC Rolling

Fine blanking is a specialized type of blanking in which the blank is sheared from the sheet stock by applying 3 separate forces. As a result, high-quality parts can be blanked that do not require any secondary operations. However, the additional equipment and tooling does add to the initial cost and makes fine blanking better suited to high volume production

- The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.

Vikas Strip Inc Services

Power Press

The power press machine is a versatile tool that cuts, shapes, blends, and presses metal sheets to achieve desired shapes. It is widely used in industries like electronics, automotive, and more. It has revolutionized the metal shaping process by offering greater force and accuracy compared to manual methods. With the power press machine, shaping metal sheets has become more efficient, precise, and streamlined manufacturing processes in various sectors.

- Power Press machine serves the multiple purposes of cutting, pressing, trimming, straightening etc.

Vikas Strip Inc Services

Powder Coating

Powder coating is a dry finishing process used to apply a dry coating material. The coating material is made up of finely ground particles of resin and pigment for color, along with other additives for specific functions such as gloss or hardness. The dry powder coating is delivered to a spray gun tip that is fitted with an electrode to provide an electrostatic charge to the powder as it passes through a charged area at the gun tip.

- The charged powder particles are attracted to a grounded part and are held there by electrostatic attraction until melted and fused into a uniform coating in a curing oven.

Journey Towards Satisfaction

Process

Simplifying processes and providing honest customer service is all it takes to satisfy our dear clients.

01

Getting a sincere understanding of the client's needs

02

Offering the most efficient and cost-effective solutions

03

Toasting to the success with cheer.

Hello

Thinking Alone?

Let us help you find the solution you need

We strive to provide you with top-notch products that meet your exact specifications, all while maintaining competitive pricing and adhering to your required timeline.